“Our doubts are traitors and make us lose the good we oft might win, by fearing to attempt”

I haven't spent a lot of time with Content Center in Autodesk Inventor. It's just one of those things I always told myself I'd get into, but like so many projects and intentions, it was set aside for more pressing matters.

But during the holiday break, I found the need to dive into Content Center, and start peeling back it's layers and start creating some custom content.

One of the things I found, was once I got into it, was it's not as intimidating as it might look at first glance. Once I dug into it, I found that, dare I say, it began to make sense.

So I decided to start sharing what I've learned (and I'm still learning). I hope you find it helpful. These are just my thoughts on what I've seen so far.

Since there are so many facets to working with Content Center, I found the prospect of doing it in one big blog post pretty daunting. So I decided to break it up into smaller bits that might be easier to digest, and yes, it's going to be a lot easier for me to write!

So for starters. Let's talk about this Content Center thing.

To get started, what exactly is Content Center?

Content Center is a series of libraries that generate standard components when you place them in an assembly inside of Inventor.

Now that's not to say that you can open up your Inventor media, and find a series of folders full of Inventor *.ipt files and copy them locally.

This is a misconception I sometimes hear. That on that media, is a whole bunch of *.ipt files you can get to.

The files actually contain the databases that build the components. So when you place a component in an Inventor assembly, Content Center builds that component and places it into the assembly for you. The functional word is "building".

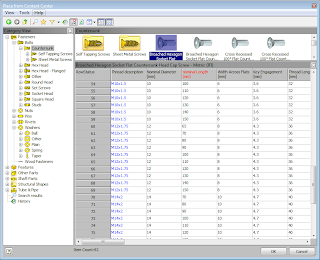

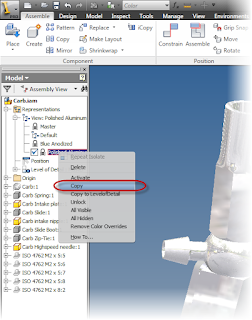

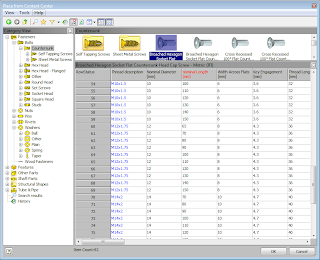

|

| The Place from Content Center Screen. This is what's talking to your libraries |

Content Center using the following procedure to build the parts.

1) A part is requested from the Content Center databases

2) It checks to see if the part has been published already.

3) If the answer is yes, it retrieves the part and places it in your assembly

4) If the answer is no, it builds it and puts it your Content Center directories, so it will be available for the next time.

So that's what they are? But where to we keep them?

There are actually two different answers to this one. There's the Content Center stored locally (Desktop Content Center) or Content Center managed via your Vault Server Console.

Desktop Content Center works great for single users, or users who don't want to install the Autodesk Data Management Server on a network server for some reason.

The advantage is that this is a pretty simple model to work with, since everything resides locally on your machine.

The disadvantage is that only the machine the Desktop Content is installed on can use the libraries. There's no sharing across machines.

So if you have several machines that are using Content Center, and you want to use Desktop Content, each machine will need to have it's own copy of the libraries. This may not be too bad, but what happens when you start customizing your libraries?

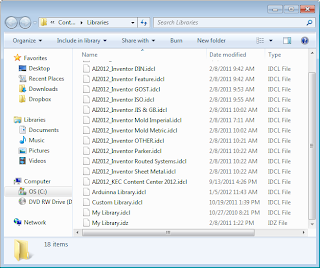

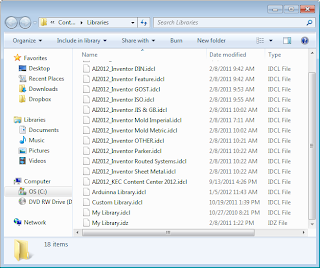

|

| The Desktop Content Libraries in their folder. |

It can be tricky to manage indeed!

Content running through your Vault Server is intended for a central Content Center shared among several users. Even if you're not using Vault, you can run Content from the Vault server. You just don't use the "Vaultiness" of Vault.

The advantage of this model, is your Content is managed from one location. The bad side? You now have a server, network connections, and possibly even I.T. to work with. So it can be a little more involved getting started. Although since everyone is now on the same set of libraries, it can be easier to maintain.

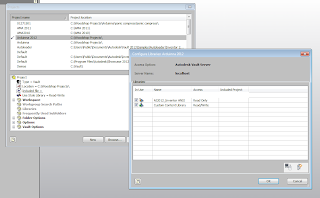

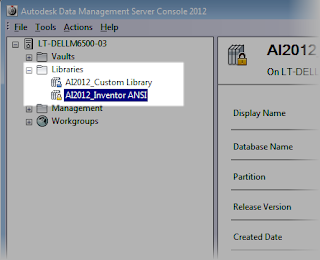

|

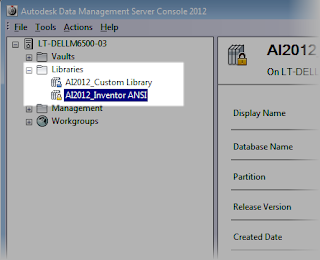

| Vault content (I only have two libraries right now) |

So these are the two options we have available to us. You'll have to decide which to use in your own application and install the appropriate one.

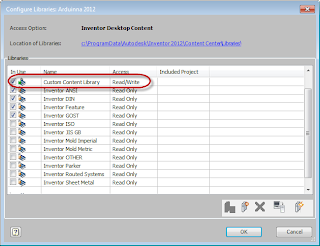

In Inventor, you can tell Inventor which it's using by going to Tools>Application Options, and choosing the Content Center Tab.

|

| Selecting which content center your running. |

That will choose where you're accessing Content Center from.

Wow, that's a lot of writing! So I'll save the rest for later. Next, we'll talk about creating custom Content Center components!

If you're wondering, I use Desktop Content. Why? It's actually, it's for a reason that is completely different than most will encounter.

I'm constantly uninstalling and reinstalling Vaults. Far more than the user in the "real world" for that reason, I run a Desktop Content Vault. That way I don't have to worry about which Vaults have what Content attached! It's as simple as that!

Click here for Part 2: Creating Custom Content for Autodesk Inventor Content Center

ADDENDUM

Thanks to

Paul Munford at The Cad Setter Out for pointing out that I overlooked a third way of using Desktop Content.

The third way would be to place the libraries on a server, and point the Desktop Content to that location in Application Options. This would allow multiple users to access the same set of libraries, without having to install Vault on the server.

I've not used this way myself. But this can be yet another way to organize your Content Center data!