Many errors I've seen (cough, made myself), are smaller, easier to miss details. One example, is forgetting to update a text field.

|

| This is not the print you want to miss a detail on. Just ask this engineer. He's got a tough boss! |

These are often notes that are hiding in a corner in the drawing. A part number in a note is a prime example.

But what if I told you there was a way to set up your template with a field that automatically read in the part number? So that every time you placed a part in the drawing, the drawing automatically read in that part number.

There is, and this is how.

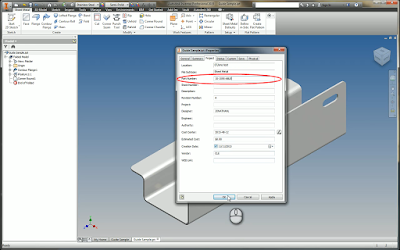

Start out by typing text, just like you have countless times in an Inventor drawing. But choose the settings indicated in the image below:

Here are the steps the image describes.

1) Start the text tool. You won't get far without this step.

2) Start typing! You'll need to get to the point where you're ready to insert the text.

3) Set the Type to Properties - Model. This makes sure that your reading the property from the model placed on the drawing.

4) Property - This is the property being placed in the text field. In my case, I'm using part number, but there plenty of others to choose from.

5) Insert - This is "pulling the trigger". This places the text in to the text field.

Next, you'll see carets with the property insert into your text editor. Part number appears in my case.

After this is done, complete typing the note you need. Once you hit OK. The text will appear on the drawing and the property's value will be read in. In my case, it's the part number 2015-48-12.

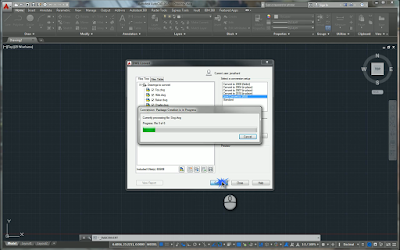

Should the property change, the field will update, wherever it's called out on the drawing, including multiple locations, if you have them.

In my example, I'll change the part number from 2015-48-12 to 15-1595-ABLE. Which, let's face it, part numbers, among other fields, can change.

Once the field is updated, the drawing will read that property from the model and automatically update.

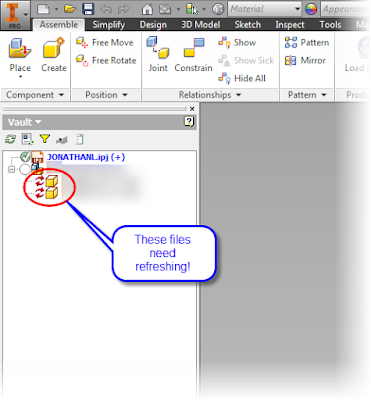

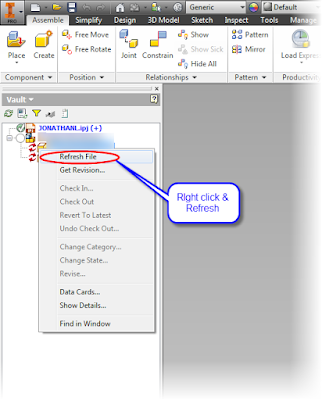

There are the steps to get a property linked into a text field. To get real bang for your buck, add required fields to your template, and get rid of some of those repetitive, and easy to forget tasks!

And look at what other fields you can add. There are plenty to choose from!

I did create a video for this one using Autodesk Screencast. No sound, I'm afraid. But life has been keeping me *just* busy enough to keep me out of my little editing room!

And look at what other fields you can add. There are plenty to choose from!

I did create a video for this one using Autodesk Screencast. No sound, I'm afraid. But life has been keeping me *just* busy enough to keep me out of my little editing room!

Photo Credits:

photo credit: Technical drawing of Darth’s chamber, by Ralph McQuarrie via photopin (license)

photo credit: Technical drawing of Darth’s chamber, by Ralph McQuarrie via photopin (license)