“Back up my hard drive? How do I put it in reverse?”

I would be the first to say that we should all be making backups of our CAD data!

Do you think I follow my own advice?

Pffft! No!

Of course I have my excuses!

- My CAD Data isn't use for production, so it's not critical.

- I work in a highly mobile environment, and everything runs on my laptop. That means I 'm not connected to a good backup server much of the time

- I'm too lazy to take 15 minutes to plug in my portable hard drive and copy my Vault Backup over to the drive.

- The most famous, used by many; (wait for it). "It hasn't failed yet!"

Are these good excuses?

Pffft! No!

So if the

The Oatmeal's Famous "Tumbeasts" made an appearance and at my hard drive, I was out of luck.

|

| Try passing this excuse off at work. |

One day, I had an epiphany that was worthy of

MacGyver.

I implemented it, and thus far it's been working well!

First I had to take stock of my assets.

- I already have a script that backs up my Autodesk Vault database and filestore that contains my CAD data.

- I have a Dropbox account that has more than enough room to accommodate my current backup

- At my home, I have an old retired computer that I use as a data server, which also has plenty of room for my Vault database and filestore.

That's enough for me!

I created a new script that moves my backup file to a Dropbox folder. In turn, that folder syncs up with my online Dropbox account, which is stored in the cloud.

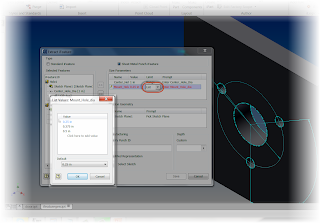

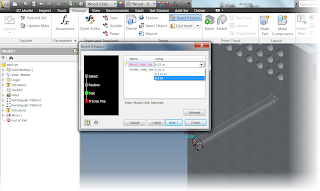

|

| My Vault Backup in my Dropbox Folder |

BOOM! Backup!

Then, I setup my old data server to sync with my Dropbox account, so now I have a backup at home, as well as on online!

BOOM! Redundancy!

I've been running this system for about a week now, and it's been working pretty well. I've restored from it once already successfully

But just like everything it's got good and bad.

First the good!

- It's a simple and effective backup strategy, especially for the budget minded.

- By using Dropbox, I can sync the backup to multiple machines, they just have to be syncing to the Dropbox account.

Now the not so good!

- Since this is a cloud backup, there needs to be sufficient bandwidth to support uploading and downloading potentially gigabytes of data.

- Online storage accounts, such as Dropbox, Autodesk 360, and SkyDrive have limited storage capacity (typically a few gigabytes until you purchase more). So monitoring usage can be important, especially as data gets larger.

Fortunately, my Vault data is about 750MB, so I have more than enough room in my Dropbox account (over 6GB), and I upload across a fiber optic line, so bandwidth isn't an issue for me, so this is effective for me.

In summary, this system probably isn't good for everybody, but for a small environment, with limited resources to purchase hardware and infrastructure, it may be exactly the ticket.

P.S. I'm sure there are those of you might be wondering why I didn't use my Autodesk 360 account. The reasons are simple. I tried my Dropbox account first, and I'm too busy (read too lazy) to switch it over. I could just as easily have used my Autodesk 360 account!

I hope this is a tip you might be able to use in your own environment!

Have another idea to create a backup like this on a budget, check out the comment section!