Every once in a while, I responsibly enjoy an "adult beverage" and ponder life.

I call it "barstool philosophy".

|

| The beverage over which much wistom is shared |

Recently, I celebrated my 51st time riding a giant rock around a "gianter" ball of fire floating in the vast expanse of space.

Only a few days after that, I found myself helping seal the fabric envelope on a 1940s vintage Taylorcraft.

.jpg) |

| The Taylorcraft with fabric over its steel tube frame |

But this time "helping" meant handing the brush to someone half my age and saying, "you're up, kid".

Somehow, when someone said, "he's the expert", and we looked around for that guy, I realized the eyes were looking at me.

It didn't seem right. There's so much I don't know, so much I haven't done yet.

I learned, or rather re-learned, teaching is a different mindset.

It's watching, guiding, stepping in, but not too much. It's saying, "if you do that, this bad thing will happen. Ask me how I know."

But we reached the finish-line in that milestone. The end product was pretty good

The kids looked at me and said , "I hope we did good. "

Little do they know, the thought going through my mind was...

"I hope I did good."

So what lessons did I learn from this anecdote? \ "old guy with experience". I'm not sure when that happened.

But happened it did. And I realized I had something to offer. While I don't know it all, the years had taught me more than I realized. Things that had become second nature by me were new, valuable lessons to those just starting out.

Somewhere, without my realizing it happened, I became a mentor.

I learned patience. I learned to look at a student and say, "You made this mistake. This is what you did wrong." And with a wry smile I'd say, with accurate self-deprecation, "Ask me how I know. I did it too.'

And finally..

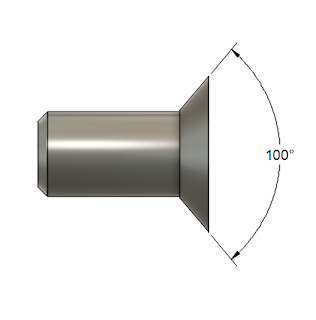

This post is pretty far removed from the Computer Aided Design Posts I've done in the past. My life and career has evolved. I'm not as deep in 3D modeling tools as I once was. The versions I use are old, and I don't use them at the level I did a few years go.

But the lesson shares common ground.

For those of use who have a little more gray in our hair, and find ourselves squinting a little harder at our screens because "someone made the fonts smaller".

Look to the fresh faced kids who were born after we graduated high school.

You might have something to teach them.