David Roberts

Construction geometry in an Autodesk Inventor sketch is one of those topics that doesn't often get talked about. It's not shiny or flashy, it just sits there and quietly does it's job.

Usually, construction geometry's job is to help position a sketch, or to help apply constraints, such as a symmetry constraint to the sketch.

The question I pose in this post is, should I change a line's properties such that the line's acts as a construction line in the "Inventor sense"?

|

| An example of the construction line type in a sketch |

So what is the difference, and why bother setting construction geometry?

Here's a sketch where I've used horizontal and vertical lines to help set position, and symmetry for a sketch. The lines are all standard sketch lines. No lines have been set to construction.

|

| Notice that all lines are "standard" sketch lines |

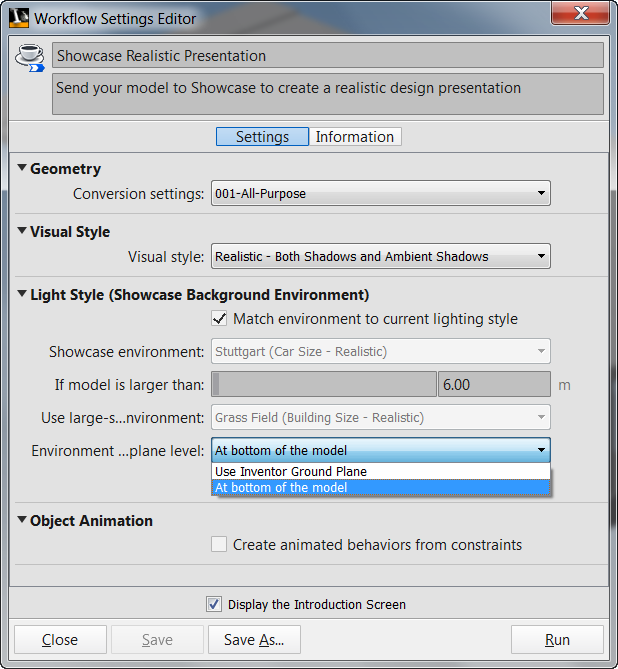

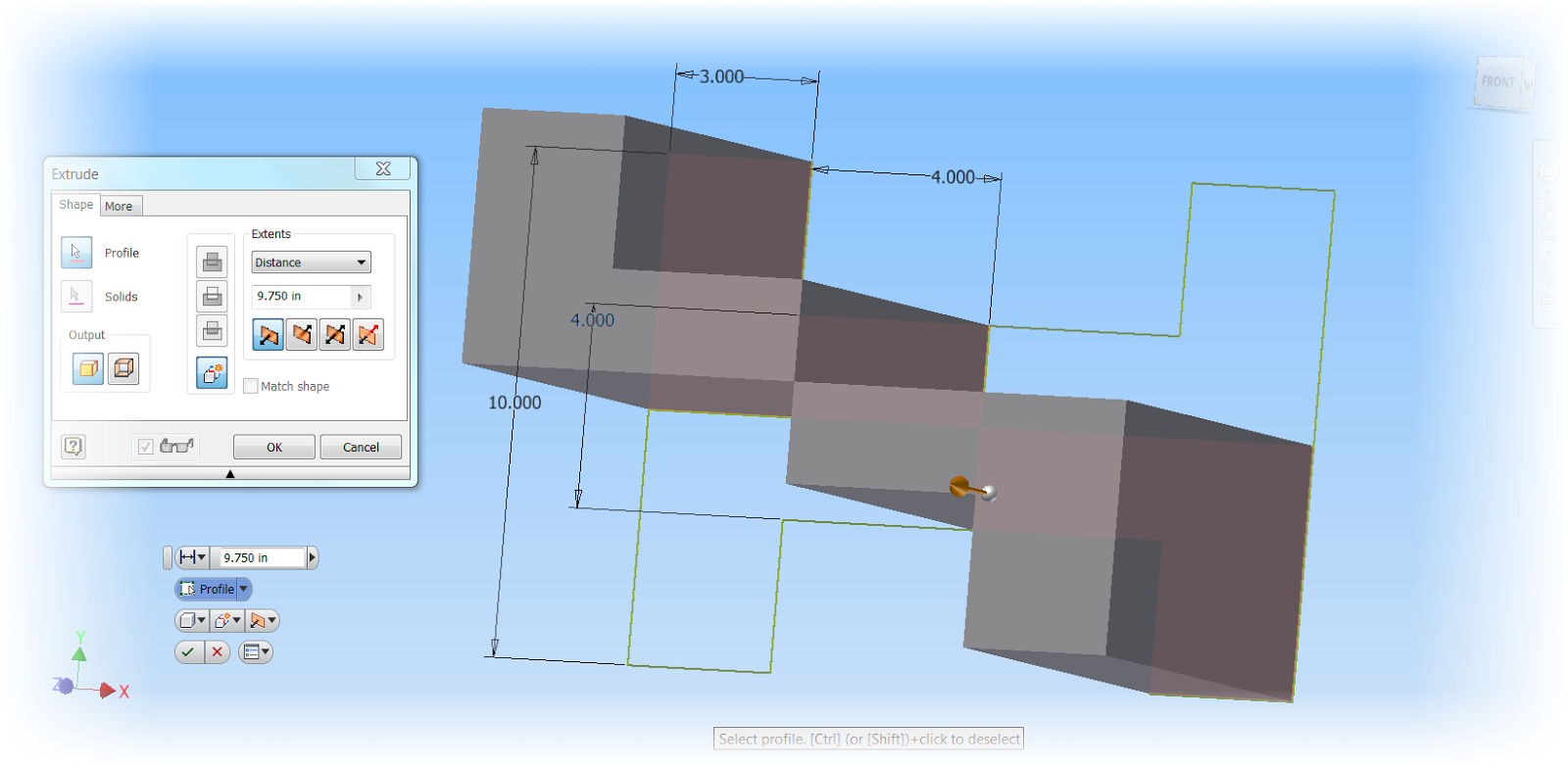

The first thing that usually gets noticed is when the sketch is extruded into a solid. The sketch is now cut up into regions, because Inventor sees each line as a potential boundary for the extrusion. In this case, I have to pick four different regions to extrude this entire sketch.

|

| The sketch broken into regions by its own geometry |

Now picking four regions might not be a big deal. It's just a few extra clicks, right? But now what if you need to put a draft, or taper angle, on the same solid.

The image below shows the result, since the sketch sees the internal lines as edges for the extrusion, it applies the taper there as well, created the "waffled" solid that might not be the desired result at all.

|

| Internal geometry can change the result of the extrusion |

I'll do that by selecting the geometry I want to change, and clicking the "Construction" icon. The line types will change to reflect the property change.

|

| The internal lines after being changed to Construction. |

|

| Now the extrusion can be created in one step. |

|

| With Construction geometry, no waffle! |

So there's a little bit on construction geometry, and why it's worth considering. There might be plenty of places it doesn't matter, but in cases like the above, it can be useful. I encourage you to take a look.

And of course, here's a video (with my somewhat raspy voice this week) below!