Proverb

With KETIV's Autodesk Manufacturing Academy getting nearer and nearer, I've been working heavily on my iLogic class. As a result, this post is about, what else? iLogic.

As I worked on developing my iLogic exercises, I found one place that would have been helpful in a past job working with electronic enclosures.

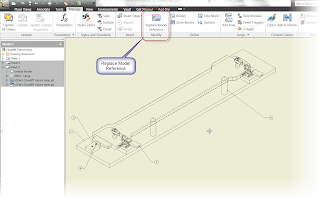

I did a lot of work with Electronic enclosures that had to meet NEMA enclosure ratings. We regularly used Hoffman boxes. I downloaded this file from their website HERE.

|

| Ahh, The Hoffman enclosure. I know thee well. |

If you want to read about the ratings, feel free to follow the link, it's good information. For the purposes of this post, let's just deal with indoor, and outdoor applications.

I dealt regular dealt with outdoor (more robust, but expensive) and indoor (less robust, but less expensive) enclosures. Needless to say, you didn't want to mix them up.

An outdoor rated enclosure in an indoor application is overkill. It costs too much, and the gains in exposure resistance aren't beneficial.

On the other hand, you don't want to use an indoor rated enclosure in an outdoor application. The box isn't designed to meet those requirements, and moisture is likely to get inside the box and damage the components the box is intended to protect.

Back when i was in this line of work, you had to check the box part number and be sure. while this wasn't difficult, it was sometimes a painstaking step, and there were times that mistakes happened.

Fortunately, one of these mistakes never made it beyond the computer, but it did result in lost time as the wrong box was removed from the model, the correct box (which may not have been the same exact size) was placed in, and the components placed in the box again.

So how does iLogic help? With one, simple line of code, I can create a warning that will tell me the rating for this enclosure. So I know right away if this is an outdoor rated enclosure, or an indoor rated enclosure.

Yes it's simple, but it can also be effective. And sometimes little extra warning is all the help we need.