Jane Howard

Last week, I was asked "Can you link parameters from one part to another in Inventor?"

I had to think back a bit. It's been several years since I had used this method, but in short, yes it can be done, and this is how to do it.

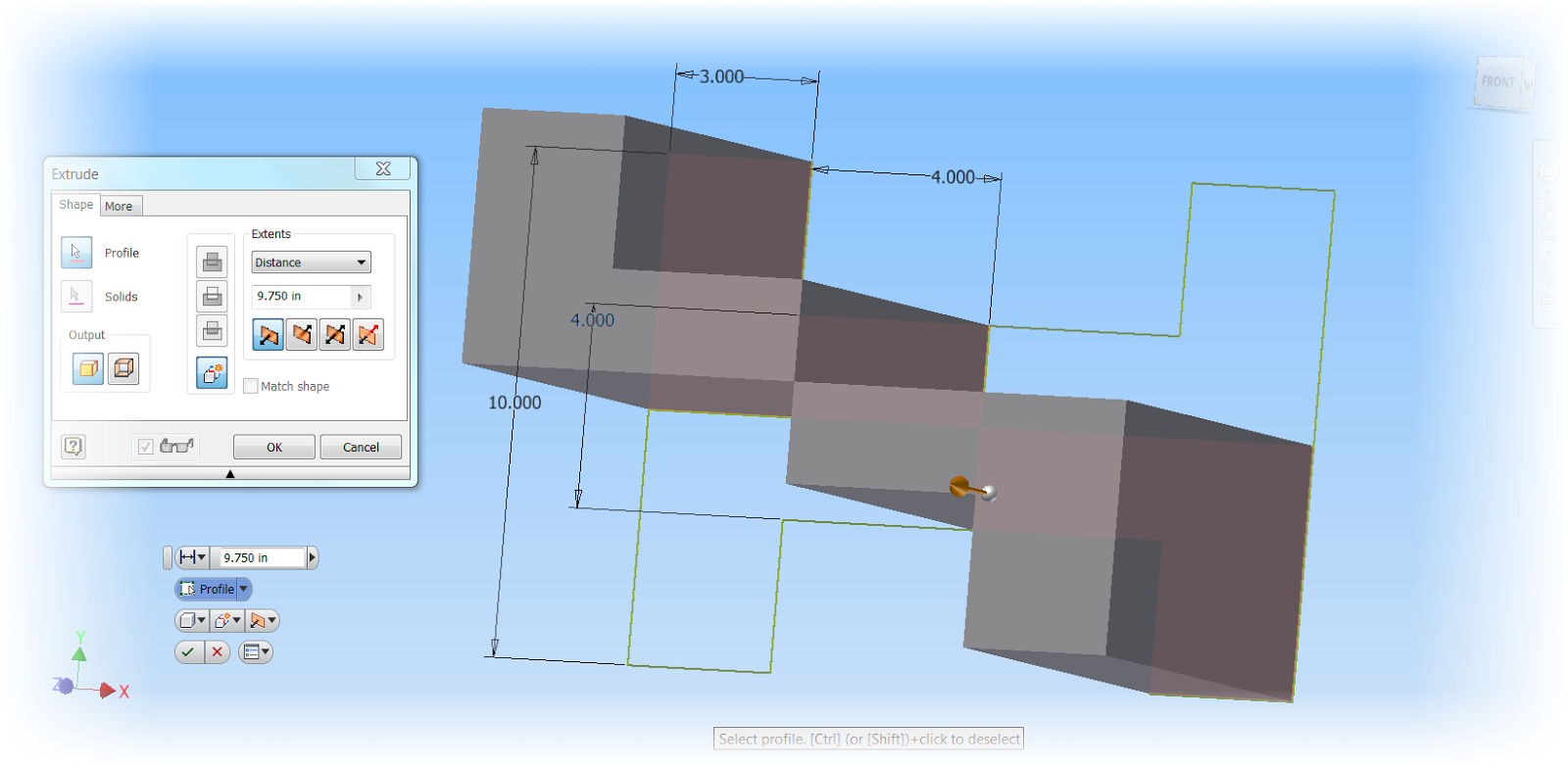

First, I have two parts, a shaft, and a base that contains a bore shown in an assembly file. The shaft has a dimension that may vary, but I know the corresponding bore has to be .025 larger than the shaft. I'm purposefully keeping the clearance large so the change is easier to see.

Looking at the image below, it's easy to tell that the clearance is far larger than .025. I'll use parameters to like the diameter of the bore to the diameter of the shaft.

|

| The shaft and bore. The dimensions are unlinked. |

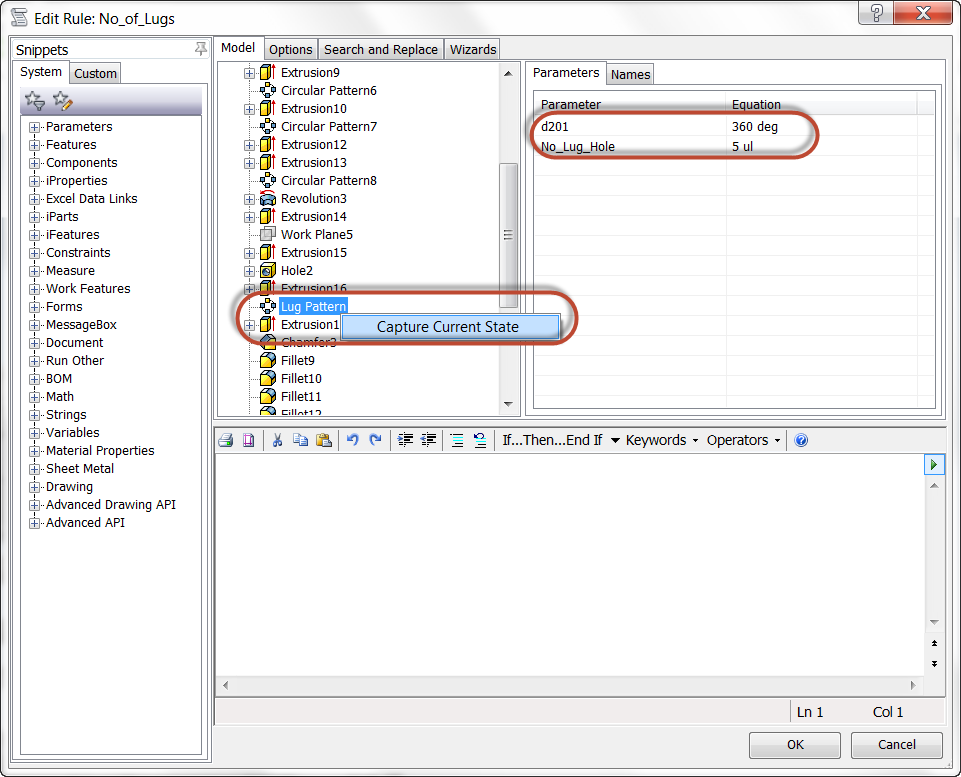

The first step to perform is to edit the shaft part, and rename the parameters that define the shaft diameter. This step isn't really necessary, but it does make the parameters easier to work with. I'm also going to check the "Export Parameter" check box.

Parameters are located on the "Manage" tab.

|

| Preparing the Parameter for use. |

|

| Showing the parameters for the bore. |

|

| The "Link" button is in the lower left of the parameters box. |

|

| Opening the file to link. |

|

| Selecting the parameters to link |

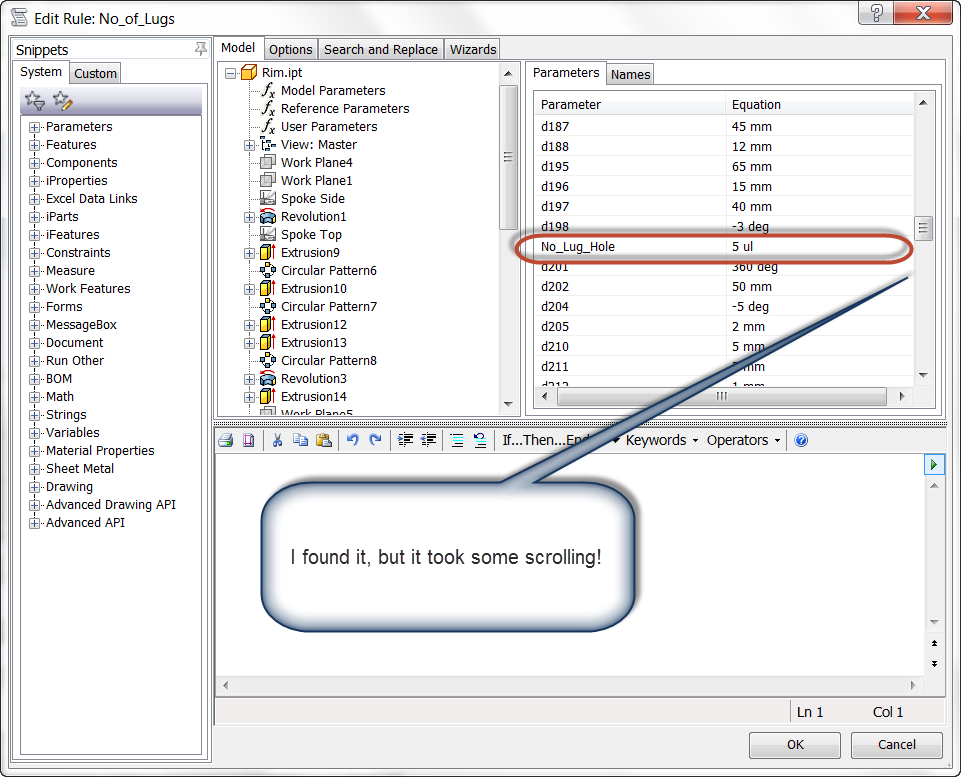

Clicking "OK", the parameter will be linked into the file containing the bore. The parameter will appear in gray, at the bottom of the parameters dialog box.

|

| The parameters are added. |

Now, an equation can be built using this parameter, adding the clearance of .025 inches. The image below shows the equation created in the parameters dialog box.

|

| The equation created. |

Closing the dialog box will reveal that the bore as already sized according to the new equation that's been added. In the image below, the assembly has been sectioned, and the shaft made flush with the bore to make the gap more visible.

|

| The gap added. |

First changing the size of the shaft.

|

| Changing the parameter. The shaft has already updated. |

|

| The bore re-sized. |

This application can be very helpful in dynamic designs where component dimensions are going to change often, and a little bit of "light automation" can be helpful.

Where is that case to be found? That's up to you!

For a video showing the steps used above, look below! In my video, I used .015 inches for the clearance. But the ideas are still the same!