The best part? It was held at the Haas Automation Outlet! What better way to see the Future of Making Things then to go somewhere the future is being made!

The Haas Factory Outlet - There's magic inside!

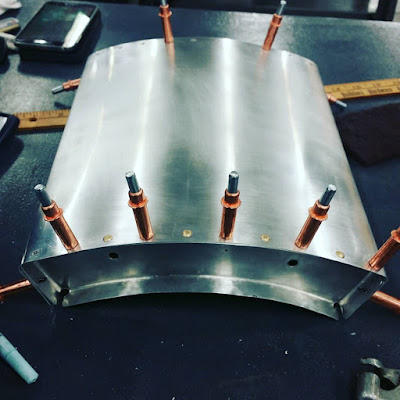

The first thing I saw inside was a little bit of manufacturing heaven! Cue the theme music from 2001: A Space Odyssey!

That was amazing enough, but next came the opportunity to see a little Fusion 360 in action! The attendees had an opportunity to see, and try, taking a part in Fusion 360 and build tool paths and G-Code.

Let's do this!

We also had the opportunity to talk among each other, get ideas, and ask questions.

Even better, we had the chance to talk to CNC machinists, and learn from there experience, which is invaluable.

I'm a far cry from being a machinist, but I have cut a few parts on a mill, and generally can create the shape I'm after if it's not too complicated. But I learned a lot from listening to them, and will be bending the ear of our own machinists when I'm back in the office.

I remember the days of "Thou shalt not take heavy cuts with your tools!" and "Thou shalt cut radii that are divisible by 1/16th of an inch!"

So shall it be written! So shall it be done!

But now, tools like adaptive clearing to remove more material more efficiently. We were also taught that there's technology exists to keep the tool moving efficiently. In effect, even though the machine is cutting a curve, the computer can compensate in such a way that the load on the machine is no different than cutting a straight line.

New technology, and a new way of doing things for the future of making things!

I answered a few questions, and came away with a few more. But most of all, I came away exited with what I'd learned, and excited with what more I could learn going forward!

Here's a few videos I grabbed! Enjoy! And get excited about what's out there!

A tool change, and back at the part!

Finish him!