Samuel Foote

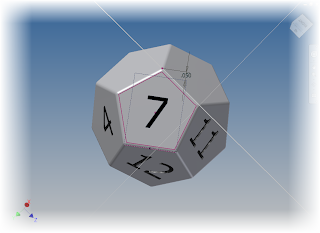

Today is Friday, and you might have noticed that in the last couple of weeks I've been challenging myself by created 3D models of gaming dice.

So far, I've created to 20 sided die, the 10 sided die, and now I've added the 12 sided die.

P.S. the view below is an embedded 3D DWF that can be panned, zoomed, & rotated!

This one ended up being the most challenging so far, at least until I got the construction method down. Once I had that figured out, it wasn't hard, just time consuming.

So here are the steps I used to build it!

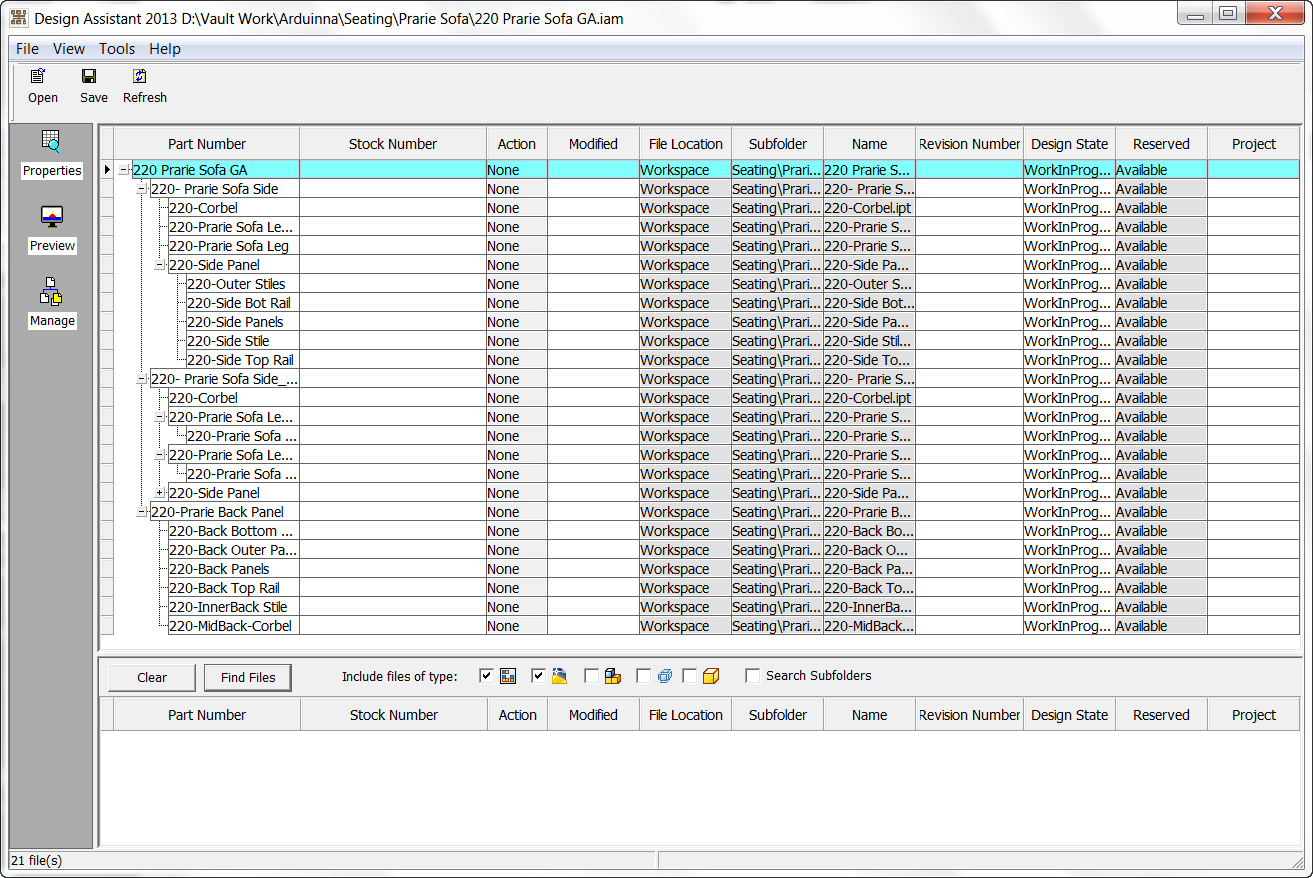

The first thing I did was locate directions on how to build the shape that eventually becomes the die. It's called a dodecahedron, and like the 20 sided die, I found it's construction on Wikipedia. It was composed of using a rectangle, and points placed at certain coordinates in space. The Wikipedia article gave me these coordinates.

|

| The construction for the die |

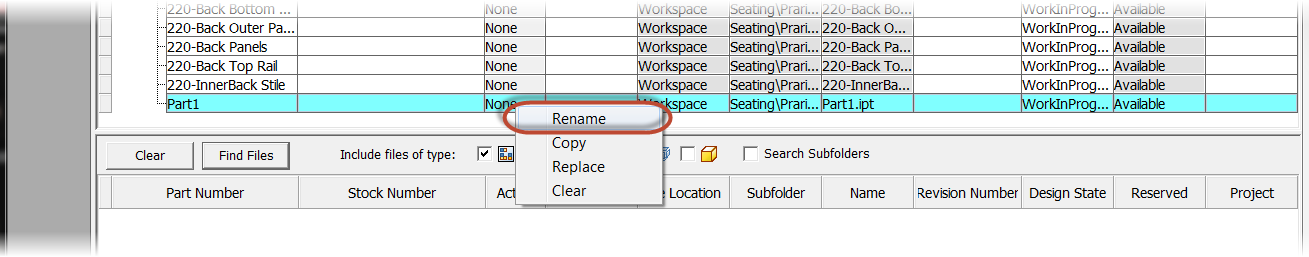

- I took this information, and using a rectangle extruded as a surface, and three rectangles, created the required points. The points are the verticies of each figure.

|

| The skeleton that starts it all |

- Next, comes the process of creating the faces. I used a workplane between three point on the skeleton. Created a 2D sketch, and started projecting geometry and sketching the boundaries of the face. This takes some time and patience.

|

| Getting started with the construction |

|

| Further along in the construction. I turned off the workplane visibility to try to make the image a little more clear. |

- Once the skeleton was finished, I went through and created boundary patches that filled in each face of the die.

|

| Now surfaces close up the shape |

- With the surfaces created, now I used the "Stitch" command to seal surfaces up, converting them to a solid.

|

| The converted solid |

- My next step was to add a fillet to break all the edges.

|

| The fillet added to the die. |

- Finally, the long, long process of adding 12 sets of numbers to the die. It's not difficult, but like most things creating these dies, it takes time, it's an exercise in more time, and more patience.

|

| The sketches in the process of getting created. |

|

|

- Finally, a drop into Showcase to give it a little flair!

So there it is, one more die out of the way. I still plan on doing the rest, 8 sided, 4 sided, and 6 sided (which is easy).

On a final note, if you want to download the models. You find them on GrabCAD and Autodesk 360.

Click here for Autodesk 360 Download

Click here for GrabCAD Download