It's a FDM (Fused Deposition Modeling) printer, in other words, it melts plastic and lays it down one layer at a time until it produces the desired result. '

At least that's what's supposed to happen!

All I can say is that it's been fun, frustrating, rewarding, and discouraging at various stages of the journey. I've tasted the sweet joys of victory, and I've muttered the bitter "F-Bomb" of defeat.

Most of all, I've realized that while I've learned a lot, I'm far from an expert. Because of that, I'm not going to tell you how to make a successful print. There are plenty of people who are doing that, and frankly, they are much more knowledgeable than I.

But what I can share are my experiences watching our 3D printer making an impact in our design process. So here I go, showing a few places where having a 3D Printer has shown itself to be a helpful part of our design processes.

One disclaimer before I get started. I can't share the real parts online. Words like "proprietary" and "security" start getting thrown around. So I have to use "surrogate" parts that represent the concept.

Thanks in advance for bearing with me!

1) The "Show and Tell"

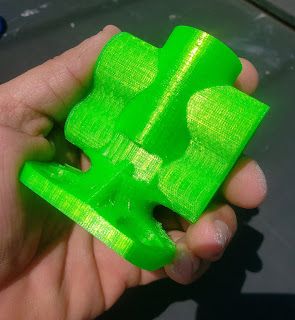

|

| There's nothing like holding a represenation of the part in your hand. |

This might seem simple at first. With 3D CAD Modeling tools, we can model our designs precisely. So why "waste time" printing a part that's just "for looking".

Well, I know I've fallen victim to being able to zoom into a small screw until it looks like a table leg. And with that, comes a distortion of scale that can affect those of us that live in the real world.

And I know I'm not the only one. I've heard more than one person say, "I really didn't think about big/small that part is!"

A particular example comes to mind. I was in a meeting where the projected image of the CAD model rotating on the wall was completely ignored because engineers and customers were drawn to the 3D printed model that represented a much more tactile experience that couldn't be experienced with the 3D model.

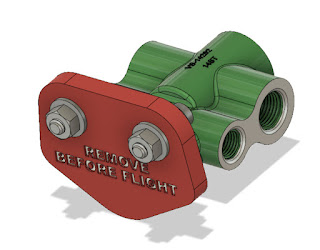

2) The "Assembly Test"

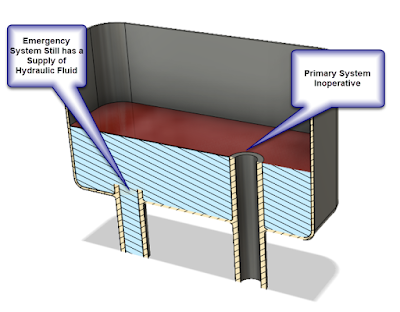

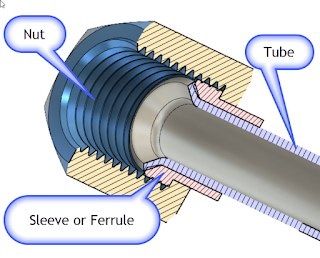

This print is in reality a series of parts that make up an assembly. It may even be a combination of real and printed parts.

|

| A sample part with a real hydraulic fitting threaded into one hole |

The purpose of this part is to ensure that the parts you've carefully designed can not only be put together, but put together easily.

|

| I can see which fitting will have to get torqued in first! |

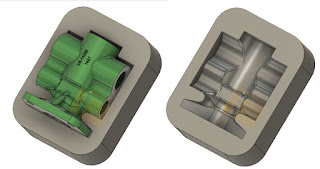

3) Tooling and Covers

I've lumped these tooling and protective covers into the same category, partially because the two sometimes blend into each other, at least where I work.

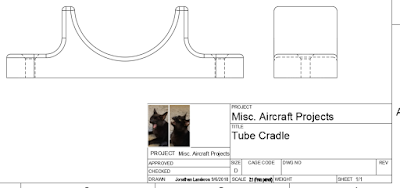

|

| An example of a protective cover that has a unique shape |

Because the 3D CAD model exists, it can be relatively quick to create a negative of the part, then print that negative as quickly as a few hours.

|

| An example of a cradle created by creating a negative of the part. |

In any case, 3D printing provided us with the ability to create odd geometry quickly, without disrupting other operations.

In Conclusion

My intention here was just to share a few cases where I've found 3D printing helpful. By no means is it comprehensive. If anything, I hope it provides a few ideas, and dare I say, inspiration.

I think it's also important that we bear in mind that 3D printing is a new tool that can supplement existing tools. Don't by a 3D printer thinking that you'll be able to shut down your machine shop, woodshop, or welding shop. .

So take these ideas and make them you're own. And feel free to share in a comment if you have a good use for 3D printing in your home or office.

Acknowledgements

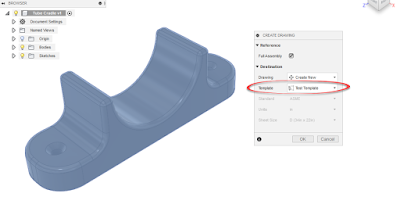

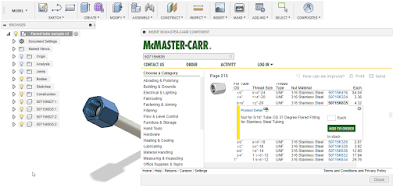

- Valve body modeled in Autodesk Fusion 360 using plans from my Aircorps Library subscription

- Hardware downloaded from McMaster Carr