By any other name would smell as sweet;

William Shakespeare ~ Romeo & Juliet

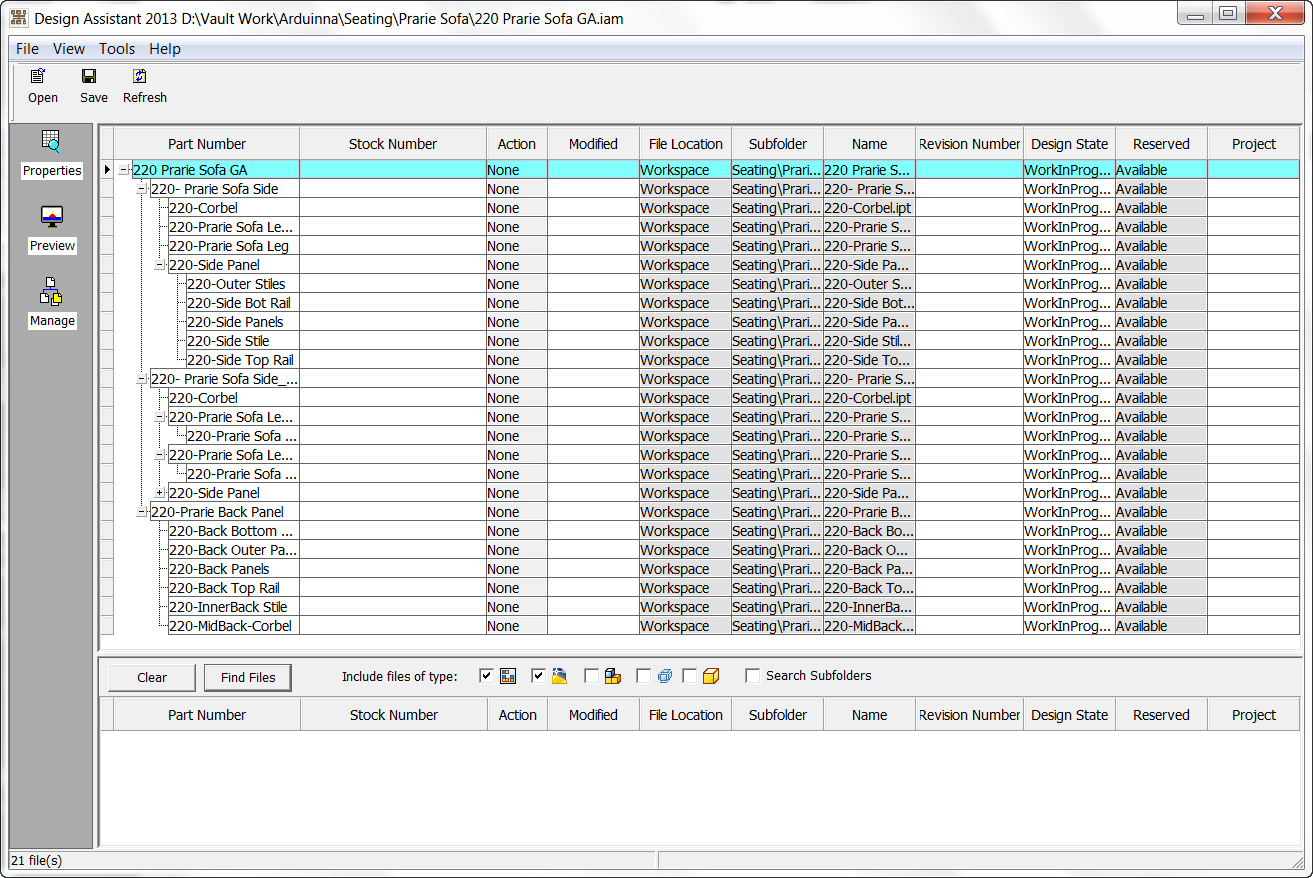

I've made this mistake more times that I would like to admit. I've been working in an assembly in Autodesk Inventor, and when I create a component, I forget to rename it and I end up accepting the default of "Part1.ipt".

Naturally, I don't realize that I've forgotten this step, and I end up creating an entirely new, default, name I never intended.

To make matters worse, I usually don't realize this until I've created a detailed part. As a matter of face, I usually realize my mistake when I'm actually saving my final version.

Essentially, what I've just described is a situation where I've created a new component, fouled up the name, and gotten to a point where undoing it and starting over isn't my best option.

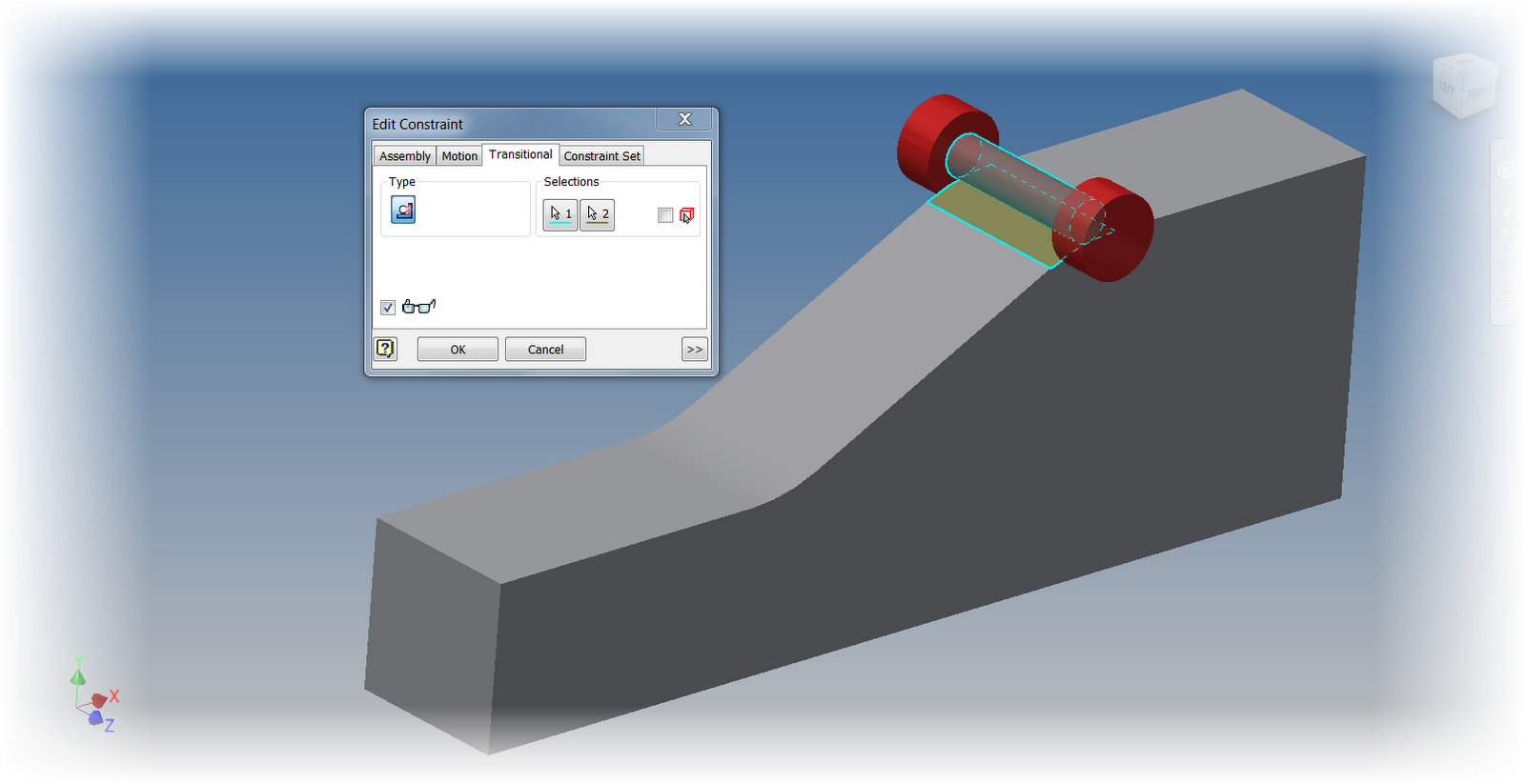

|

| The assembly with the part I named wrong |

So how did I manage to get out of it?

My first option was to check the files into Autodesk Vault, and rename them there. That option works just fine, and I've used that in the past.

But what I really wanted to do, was rename the files before I put them in Vault. I just didn't want to check the assembly in just to rename them in Vault.

Before I continue, I have make sure to note that the file I'm renaming is NOT yet in Vault. If it was in Vault, then I'd use the Vault Rename tool. But I digress....

To rename the offending file, I used a tool called Design Assistant, which is included in Inventor, and doesn't require Vault. As a matter of fact, it doesn't need Vault at all.

What is Design Assistant? How does it work?

Design Assistant is a tool, included with every installation of Autodesk Inventor that is intended to help with file management. It has several tasks, but one of which, is to rename files So where is it located, and how did I get to it?

- My first step to locate Design Assistant was to go to Windows Start>Autodesk>Autodesk Inventor 2013 and locat Design Assistant.

|

| Accessing Design Assistant |

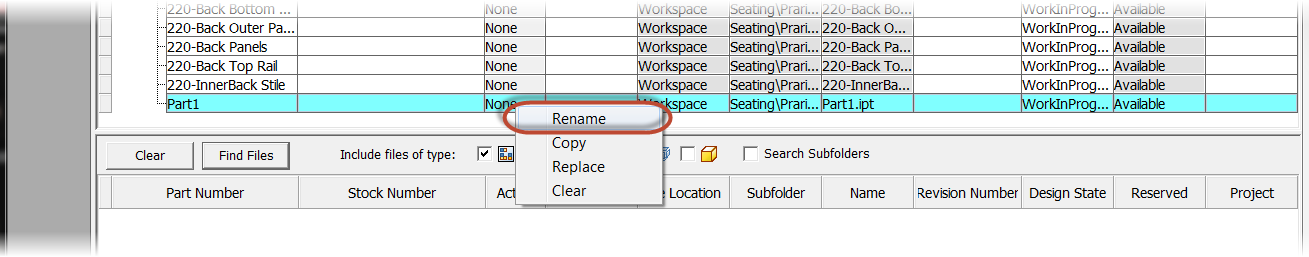

- Starting it up, I need to choose the assembly containing the part I've messed up. Once the assembly is open, I chose the "Manage" option. Now I can see the components that make up the assembly.

|

| Locating the offending part in Design Assistant |

- In my next step, I find the component I need to rename. I right click on the the "Action" cell, and choose "Rename".

|

| Right click and choose "Rename". |

- Now the component's row highlights. Next I choose the component's name and select "Change Name"

|

| Choose "Change Name". Notice the Action cell has changed too! |

- A dialog box opens and I can now rename the file.

|

| Renaming the fie |

- With the file renamed, I save the changes, and I'm ready to go.

|

| All that's left is to click "Save" |

|

| And I'm done! |

- I can now check the files into Vault, and the correct name goes into Vault, without requiring that I go in and change it.

|

| Checking into Vault, and I'm done! |

So that's how a file can be renamed using Autodesk Inventor's Design Assistant. But before I give you the video, there are a couple of things to note!

Yes, I know I'm repeating myself. But I think it's worth repeating!

- Design Assistant doesn't require Vault. So if you're a user who isn't using Vault, this can help out a great deal.

- However if you are using Vault, don't use this to replace Vault's Rename tool. As a matter of fact, if the file is already vaulted, make sure to use the Vault Rename tool! Design Assistant should only be used for files that aren't in Vault yet! Failure to heed this warning could lead to file resolution issues, and being excessively mocked by your peers!

And if there's any experience you'd like to add, throw a comment in below!

***************************Edited October 10, 2013**********************************

A comment below mentioned that they had lost links to drawings when using the process. Most of my work with Design Assistant didn't involve drawings. I rarely, if ever have drawings created when I'm using Design assistant this way.

However, I did find a link on the Autodesk Discussion Group here, that addresses this.

Sorry if I caused any confusion, I hope this makes this tip a little more complete.